low compression leak down test good|compression tester vs leak down : Big box store A compression test uses the engine turning to generate the compression in the cylinder for the compression stroke, in which both intake and exhaust valves are closed. A .

20 de dez. de 2018 · Check out the new Gotham Season 5 Sneak Peek starring David Mazouz! Let us know what you think in the comments below. Learn more about this show on Rotten T.

{plog:ftitle_list}

Resultado da Detran / Portal (Multas) NADA CONSTA DO VEÍCULO (RENAVAM) Siga corretamente os próximos passos: Digite o Renavam no campo de .

If you have a solid stand to hold the engine you could spin it with the electric starter to do a compression test. Unless you can run the engine on that stand you'll be doing a cold test so expect the numbers to be low. A leakdown at BDC won't tell you anything since one valve . The good leak down test says that the valves will close (forced by pressure), but not seating naturally in their own motion. It also says that the rings are good and the block is . Modern engines have nice computers that can sense when a cylinder is not performing properly, but for our older engines, the way to check and see if the engine is .

The leak down test measures the percentage of pressure loss in each cylinder, indicating potential leaks or worn piston rings, while the compression test measures the .

If you find a cylinder with low compression, a leak-off test will tell you why. If air leaks out of the exhaust or intake manifold, a valve is leaking - cylinder head repair required. If . A compression test uses the engine turning to generate the compression in the cylinder for the compression stroke, in which both intake and exhaust valves are closed. A .

What a leak down tester does, is compare the line pressure of an air source to the flowing pressure when the cylinder is pressurized. The air source is connected to the tester and then the tester attached to the spark plug hole . WET IT DOWN. With a dry leakage test, you can tell whether the blow-by problem is due to the rings or taper wear in the cylinder by turning the crank to reposition the piston halfway down the cylinder. Cylinder wear is always greatest at the top, so moving the piston down from TDC should reduce the amount of leakage if taper is the problem.

So whilst speaking to a guy at the local cylinder head shop about valve and port cleaning he mentioned that even though my compression tests on all 6 cylinders were spot on that I should in addition do a leak down test. I just assumed that if my compression was spot on then there’d be no leaks and therefore I should look somewhere else. So . I do a hundred leak down test every year on engines. The leak down test is far more telling and diagnostic than a static test. To me a static compression test is worthless. I use on my engines 80 psi test pressure and with a nice tight normal engine I see 76-78 residual pressure. If you have leaky valves or rings it will show right up. Compression test was good ~132- 143 psi. Installed the rebuilt distributor and recurved for an E and still had the bad miss. Could not get a reading for setting the timing, the timing light read rpm but the light didn't flash.

I understand that both cylinder leak down and compression tests are used to test for cylinder head, cracks, warps, and gasket leaks. . a compression test will quickly tell you if any individual cylinder has low compression. a leakdown test is a little more involved and will help pinpoint where you're losing compression. but if the engine is .The cylinder leak down test allows DIYers and professionals to assess the integrity of an engine’s internal components. This test, indispensable for measuring the capability of an engine to hold pressure, is an integral part of any thorough engine health assessment due to its ability to pinpoint issues that rob you of power and reliability.

Combining the results of a leak down test with a cranking compression test can indicate an engine's potential. For a street engine, cranking pressure between 175 and 200 psi is ideal. This is a . One way to do that is by doing a Leak Down Test. Leakdown Test. The compression test will tell you that you have a problem, but the leak down test will lead you to where the problem actually is. The basic premise of the test is to pressurize the cylinder and look and listen for leaks. A higher compression ratio means that the pressure inside the cylinders is greater, which can lead to more power and efficiency. However, it also means that the engine may be more prone to knocking or pinging, which can damage the engine over time. A lower compression ratio, on the other hand, means that the pressure is lower, which can result in . You then take the reading and see what your leak down % is. (Here is a good video of the procedure) Again, you are looking for overall leakage as well as the difference between cylinders. . If you find a cylinder with low compression, a leak-off test will tell you why. If air leaks out of the exhaust or intake manifold, a valve is leaking .

The compression test is the more common of the two, requiring less specialized equipment than the leakdown test, but both are valuable ways of tracking down potentially serious engine problems. Let’s take a closer look at the step-by-step process for using a leakdown tester, how to interpret the results, and some common signs of an engine . Yesterday I did a compression test and then a leakdown test. The compression was low e.g. 90 across a few cylinders on different banks. I got a different (new) gauge - same result. The "hold" valve at the gauge on my gauge was leaking. I . Since the engine sucked in dirt, I assume the cylinder walls are scored and the compression was leaking past the rings. When I did the compression test, the 3% leakage went through the rings, not the intake or exhaust valves. Since the engine has low compression, I assumed it would fail a leak-down test. Please help. Thank you!!

A leak down test involves pressurizing each cylinder of an engine and measuring the amount of air that continues to leak out. If there is a significant amount of air leaking out, it indicates that there is a problem with the engine’s internal components. . When an engine has low compression, it means that one or more cylinders aren’t . Okay so on friday i did a compression test just for educational purposes and found 150 Psi all around after 3 compression strokes. I decided to do a leak down test just for the heck of it and i really didnt have much else to do, and I found 8% leakage in all cylinders except for numbers 3,4, and 7. Those three had 20% :confused which was a bit shocking to . Other tests are mechanical, like the compression test and cylinder leak-down test. Today we’re going to be discussing the venerable leak down test, and not only explaining how it’s performed, but what it can tell you, .

compression test is a waste of time with a modern 4 stroke. why? because they have an auto decompression system on the cam. A leak down test is a much better way to monitor the engine without a tear down. Inspect the valve clearances, adjust if needed and ride. The key difference between the two tests is that a leak down test introduces compressed air into the cylinder via the spark plug hole and measures any leaks, whereas a compression test measures the compression generated by the engine. Remove the Oil Cap and Check for Pressure. This method is quick and easy for diagnosing low compression.

Low compression in one cylinder usually indicates a bad exhaust valve. Low compression in two adjacent cylinders typically means you have a bad head gasket. . A leak down test requires the removal of all the spark plugs. The crankshaft is then turned so that each piston is at top dead center (both valves closed) when each cylinder is tested . Easy to remember, If your engine has good compression numbers, no need for a leak down test. Bad compression numbers, then do a leakdown to help pin point the problem before paying for a teardown and repair. Compression test always first, leakdown only if needed. Not so tough, eh. _____ Leak-Down Test Insights. A leak-down test is another way to diagnose low compression in your engine. Here’s how to perform a leak-down test: Start by removing the spark plugs from the cylinders you want to test. Screw the leak-down tester into the spark plug hole, and then pressurize the cylinder with air.In our opinion, all cylinders should be within 4% of each other. If you have a cylinder that has excessively low compression, try adding a few drops of oil. If the compression comes up, you have a ring seating problem. . A leak down test is especially good at discovering leaky valves. We use much less pressure (about 80 psi) than is normally .

A pressure gauge is connected in place of the spark plug. The engine is then cranked to create a pressure reading. A compression test is a good way to check the engine’s ability to create pressure. The gauge reads the positive pressure created by the cylinder. Loss reading An engine leakdown test is a compression test in reverse. Good Compression and bad leak down test results . After trying every different thing I decided to go back to the basics so today I did a vacuum test,a compression test and a leak down test on the engine to try and trace the root of the issue. First I ran the car with a vacuum gauge on it and noticed the idle vacuum was a little low even when . It took a while but I finally got to doing a leak down test and the leakage on cyl #1 was >80%, which could have been ok if the 80% of the leaking air wasn't coming from the crank case breather. Haven't decided yet what to do with it, I'm not up for machining the bores and all that jazz, so it's probably headed for a new owner unless I find a .

leak down tester instructions

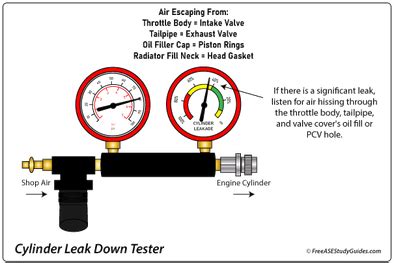

The compression tester gives you cylinder-by-cylinder compression and lets you find if any cylinders are low, but it’s the leakdown tester that helps you find why compression is low. A leakdown tester is simply a pair of pressure gauges, an input connection to an air compressor, and an output connection that threads into the spark plug holes.A compression test is an easy way to asses the mechanical health of an engine. The engine's valves, piston rings, cylinder walls and head gasket must all be in good condition to hold compression. A leak down test will allow you to troubleshoot a low compression cylinder. Jump to Leak Down Test. Compression Test

leak down tester auto zone

leak down test without tester

A coesão refere-se a estrutura e organização de um texto. Para isso, todas as suas partes devem estar interligadas através de elementos conectivos. Enquanto a coerência remete .

low compression leak down test good|compression tester vs leak down